Aug 11,2023

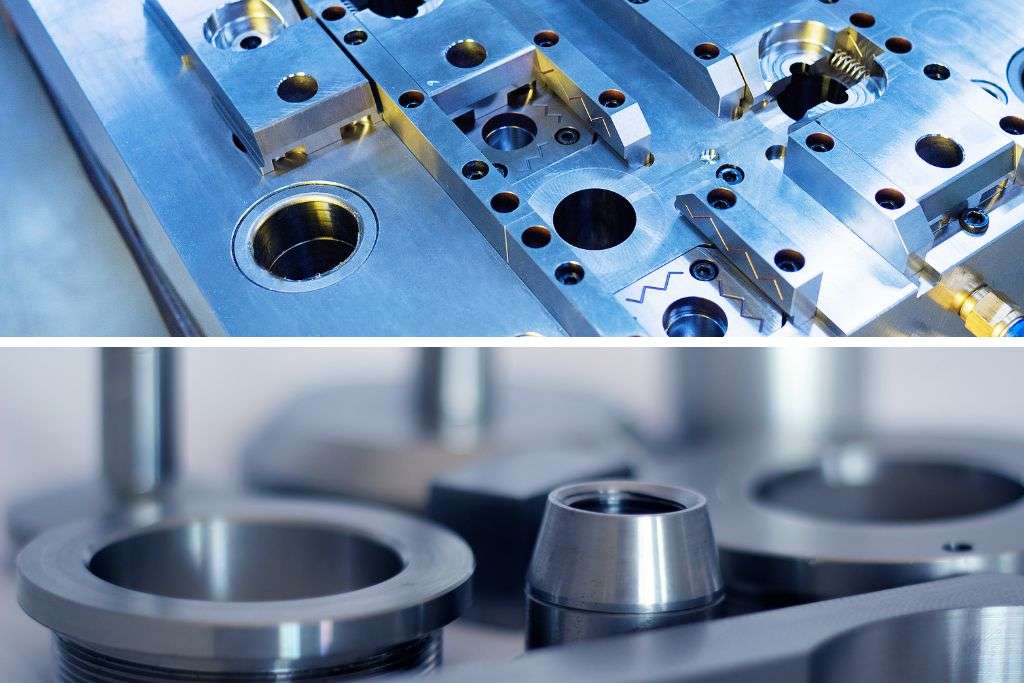

Every application has a different requirement for materials in production. Some applications need soft materials, and some need hard ones. Whenever we discuss high-endurance jobs, metals are the most efficient materials there. Similarly, some people get confused with identical-appearing metals with their properties. Since they look similar does not mean they have the same properties. In this scenario, we are going to compare tungsten steel and stainless steel parts for you. Their physical properties define their success rate and also a failure in wrong applications. Using the wrong type of metal can cause trouble for manufacturers of machine parts, medical equipment, and tools.

To clarify the vast differences between them, we have brought around seven factors for you. This will save you from wastage time, cost, and material in production. Purchasing the right type of material will always make way for efficient production.

Though both metals are tough and resilient, tungsten is among the toughest materials in the world. Tungsten steel parts are extremely hard-wearing, which makes them perfect for robust activities. At some point, stainless steel cnc parts may give up to excessive wear. However, tungsten steel parts can withstand excessive pressure and endurance from external force. Thus, tungsten steel is preferred for high-pressured activities, where the survival of metal is ensured. Tungsten steel is commonly used for the tools of cutting, drilling, hammering, and machining. It is because of its excessive-toughness level. However, stainless steel is also used in some tools for medium-level pressure.

The melting point shows the level of endurance of any material. If you want to know the reason for tungsten steel parts’ survival in extreme heat, the reason is heat-resistance level. They have a very high melting point, which is why tungsten steel is widely used for high-temperature environments. These parts can survive for a long time in boiling machines. If we use stainless steel parts, they can not withstand extreme heat as compared to tungsten steel parts. The heat resistance of tungsten is close to diamond, which is the hardest material in the world. It makes tungsten steel suitable for every extreme application, like die-casting. It can bear pressure, heat, and chemical reactions consistently.

Since SS parts have less hardness than tungsten steel, they need less power for machining. In the production of machine parts, stainless steel is widely used. But when it comes to powerful endurance, tungsten steel has to be used. The production of tungsten steel parts needs more power, time, and effort from machines. Furthermore, machines need more powerful metals than tungsten steel for machining purposes. Professionals avoid using any weak metal in this machining because that metal will not work on tungsten steel. More power and energy will be applied, which will increase the cost of production. Thus, ready-made tungsten steel parts are not available mostly. Customized orders have to be given for their production, and SS parts are available all the time.

Price comparison makes it clear that tungsten steel parts are high-priced. Stainless steel parts are somehow affordable for many buyers. TS parts are expensive because of their durability and resistance abilities. In addition, this metal is not commonly used, and it is kind of a niche in the metal industry. Just some specific consumers purchase them for limited consumption. Likewise, Tungsten steel parts are used in machines for cutting, as well as they are used in jewelry. To toughen the jewelry, tungsten steel works really well. As a result, the cost of production is high, and the price becomes higher than SS parts.

Magnetism brings a massive difference between these metals, which also restricts their consumption in some applications. Sometimes you need magnetic parts, and sometimes not. Tungsten has no magnetism in it, which makes them suitable for magnetic fields. Magnetism does not have any effect on them, and their performance remains constant in magnetic environments. Stainless steel parts can be used for magnetic purposes in many applications. However, TS parts can be used to prevent any kind of magnetic disturbance. Radar, medical equipment, and similar machines are supposed to be prevented from magnetic waves. If you use SS parts in them, there will be a problem for the users. To avoid that problem, it is better to use non-magnetic metal like tungsten steel.

TS parts might be ahead benefits than SS parts, but SS parts have high oxidation resistance. Consequently, the corrosion level is low in stainless steel parts against oxidation. Oxidation has very little impact on SS parts. However, other environmental effects on TS parts are low. Tungsten steel can survive lots of impacts of airborne particles but oxidation. SS parts can withstand it better than TS parts. It is where SS parts have an edge over TS parts. If you are willing to install machine parts in an environment with high oxidation levels, SS will be a better option against oxidation. If we compare them in terms of long survival abilities in harsh environments, TS will have better results than SS. SS can give good results only against oxidation.

The higher the ductility, the higher the shaping ability will be. Metals like stainless steel have high ductility, which makes them suitable for shaping. However, tungsten steel can not be formed into different shapes because of low ductility. Too much force can turn SS into desired shapes but not in the case of TS. Tungsten steel parts need different methods for cutting and shaping. Though, the shaping is possible mostly with soft metals, whereas SS is a hard one. Stainless steel can work well for bending, twisting, and stretching purposes.

Once you are clear about their differences, there will be no risk of breakage and waste of materials in the manufacturing of metal parts.