Aug 11,2023

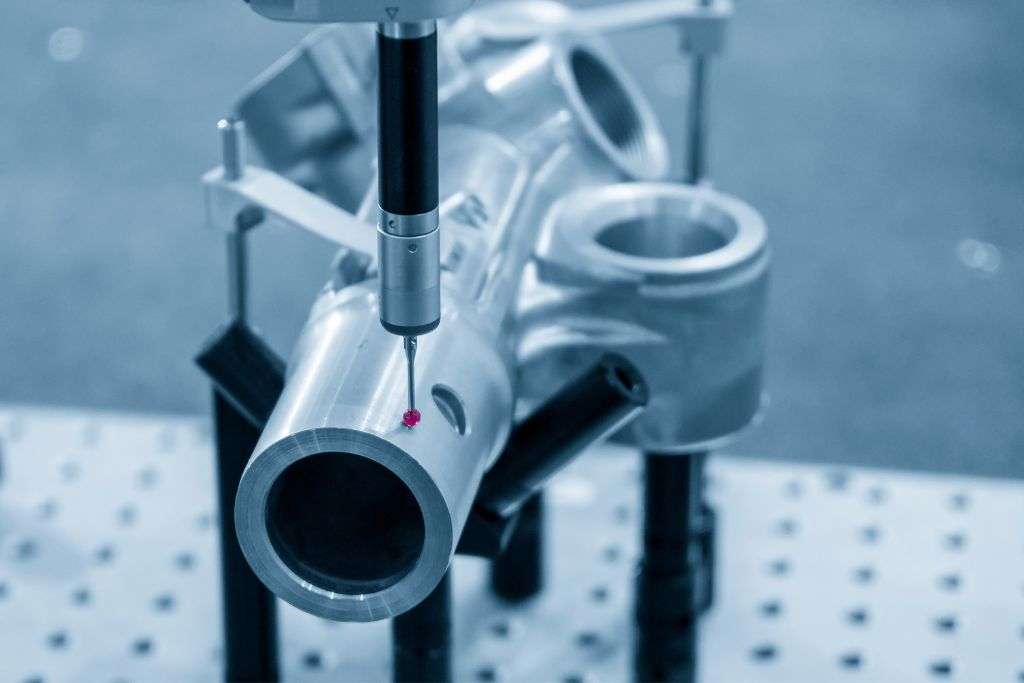

Aluminum, with its remarkable blend of lightweight durability and corrosion resistance, has become a staple material across industries. From aerospace components to consumer electronics, the demand for precision aluminum machining parts is steadily on the rise.

But in this meticulous process, the choice of tools can either make or break the results. Let's delve into the world of aluminum machining, exploring the key factors in tool selection that can elevate your outcomes.

Before we leap into the tool selection journey, it's crucial to waltz through the basics of aluminum machining. This dance involves sculpting and crafting intricate parts from aluminum blocks, a process that requires finesse, expertise, and the right set of tools.

The world of aluminum machining isn't all smooth sailing. It comes with its own set of challenges:

Heat Dissipation Dance: Aluminum tends to conduct heat rapidly, which can lead to tool wear and thermal deformation. Your tools need to be equipped for this heat-intensive tango.

Chip Control: The creation of chips during machining can sometimes be erratic due to the material's unique characteristics. Tools that ensure smooth chip evacuation take center stage.

Material Matters: Just as dancers require the right shoes, aluminum machining demands the right tools. Carbide tools, often coated for enhanced durability, are a popular choice for this choreography.

Geometry Jive: The tool's geometry can greatly impact the machining process. Opt for tools with sharp cutting edges to conquer aluminum's dance floor smoothly.

Coolant Choreography: Coolant is your partner in this dance, helping manage heat. Choose tools with effective coolant delivery systems to keep the temperature in check.

Diamond-Like Carbon (DLC): This coating glides gracefully over aluminum, reducing friction and enhancing tool life.

Titanium Nitride (TiN): TiN coating adds a touch of hardness to your tools, making them more resistant to wear and abrasion.

In the realm of aluminum machining parts, tool selection isn't just a technicality – it's an art form. By choosing the right tools, you're orchestrating a symphony of efficiency, precision, and quality.

Embrace the challenges, master the steps, and let your tools lead you towards machining excellence. As aluminum continues to shape industries, remember that the right tools are the partners that will dance with you to success.

In this intricate world of machining, your tools are your partners on the dance floor. Just as experienced dancers choose their steps wisely, manufacturers must select their tools meticulously for the art of aluminum machining. Through understanding the challenges, navigating the selection process, and embracing the nuances, you can lead the symphony of machining excellence.

Absolutely, but remember that different alloys might have unique characteristics. It's wise to adjust your dance steps (tool settings) accordingly.

Indeed, high-speed steel tools can work, but carbide tools often steal the spotlight due to their enhanced durability.