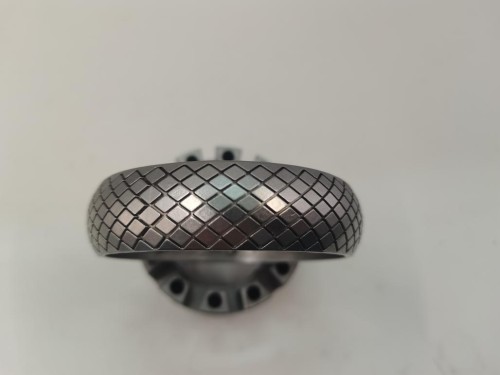

1. Material: Adopts metal materials like aluminum alloy and stainless steel, boasting high strength, wear resistance, and corrosion resistance. This ensures the parts remain stable and durable during mechanical operation, extending their service life. 2. Processing Technology: Employs CNC precision machining to accurately carve complex shapes, holes, and surface textures (such as diamond patterns). Texture treatments on some parts enhance both practicality and visual appeal. 3. Shape and Use: Textured parts: For instance, ring - shaped pieces with diamond patterns can be used in mechanical components needing increased friction (e.g., operation knobs) for easier grip and control. Cylindrical textured parts: May function as transmission knobs or connectors, enabling smoother rotation via surface textures. Ring - shaped structural parts: Multi - holed ring components are suitable for mechanical connection and positioning. Similar to flanges, they achieve inter - component connection through bolt fixing. Irregular metal parts: U - shaped or block - shaped parts with holes act as mechanical supports or fixing bases, stabilizing other components and ensuring mechanical structure reliability. 4. Product Advantages: The CNC process ensures high precision and accurate dimensions, fitting well with precision mechanical systems. The combination of metal materials and surface treatments balances strength and performance. Diversified shapes cover diverse mechanical scenarios like connection, transmission, support, and fixation, offering strong versatility.